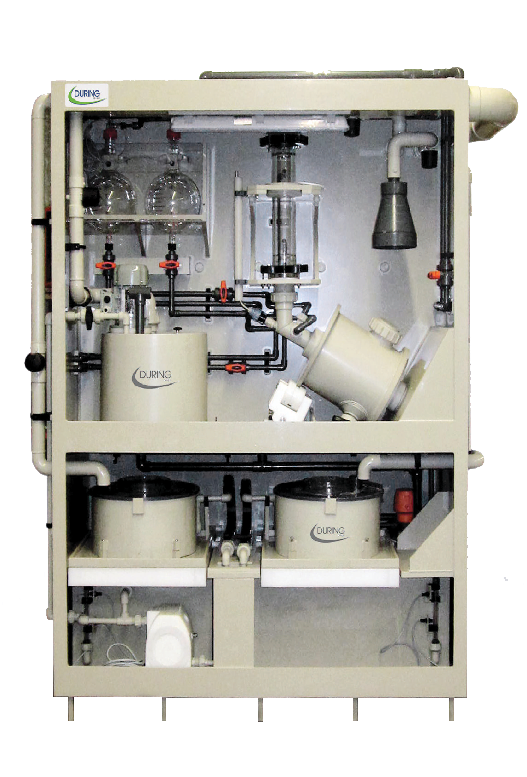

TB1 – Gold Recycling Plant

With our Series 7 TB / TB 15 / TB 30 and TB 60, we have developed a very successful product line. With the experience from the very well-functioning systems of this series we have now, after more than

a year test run a system developed with a capacity of just one kilo. The special feature of this system is that the customer can order a system which can meet all the require- ments of a professional

separation plant. The system is characterized in particular by their compactness and at the same time by your edibility. So we have in this system even unprecedented variety packed. Even the strictly necessary air scrubber is integrated in this system.

Output / Day : 300 g - 1,5 kg

Dimensions LxWxH mm : 1.800 x 800 x 2.000

Connection : 400V 50Hz / Wasser / Druckluft

The system is in a hood made of PPH integrated. Screws, shafts and other metal parts are made of titanium.

The basic equipment includes the following system components:

- Housing with hood made of PPH

- Two liter units FT 400 / S with a vacuum pump

- Two acid glass container 5 liters

- Precipitation tank from PPH with agitator

- Fume scrubbers with storage tank, pump and fan

- Exhaust air cooler made of glass

- Tumbler made of PPH

- Switch cabinet

Accessories:

- Rolling shutters made from plastic with an electric drive for closing the front of the machine

- Automatic level control for the acid container, for the storage tank from the air washer and for the wastewater tank

- Waste water tank with pump - Wastewater tank from PPH with pump for emptying

- Automatic NaOH dosage for the air scrubber - Dosing pump for NaOH with pH measurement

- Automatic H2O2 dosage for the air scrubber - Dosing pump for H2O2 with time control

- Steam generator 4 kW - Steam generator 230V 50 Hz / 4 kW with steam lance made of titanium and shut-off valve made of PVDF