Nitrogen is used as inert or purge gas anywhere, where oxygen reduces the shelf-life of products, impairs their quality or could result in critical or undesirable reactions. Whether your company is specialized in food processing, chemical, electronics manufacturing or laser cutting, a dependable supply of industrial gas is crucial. Compared to the on-demand delivery of gas bottles or tanks, on-site production of gas offers a wealth of advantages ranging from cost savings to continuous availability, this is exactly what we provide.

PSA Nitrogen Generator

A line of robust, reliable nitrogen generator based on Pressure Swing Adsorption (PSA) technology using state of art adsorbents to produce nitrogen from compressed air, allowing continuous availability at a very competitive operation cost compared to merchant gas supply.

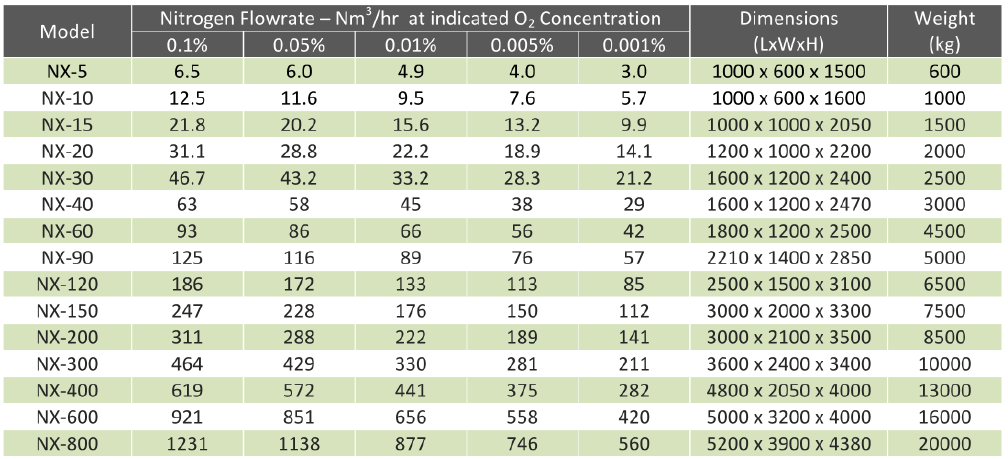

The various models of PSA nitrogen generator systems offered by ANOX generate nitrogen at purities ranging from 95 – 99.999%. Various sizes are offered from small to large flow rates in order to meet specific nitrogen needs

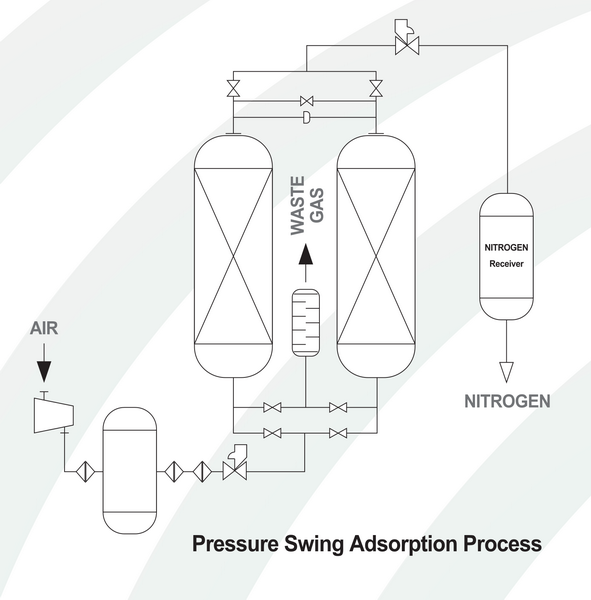

How Nitrogen PSA works

Ad-sorption is the physical process of separating molecules. Our Pressure Swing Adsorption (PSA) systems generate nitrogen, by separating it from the oxygen in ordinary air. A vessel containing carbon molecular sieve, or CMS, is filled with compressed air. The smaller oxygen molecules are adsorbed by the sieve material while the larger nitrogen molecules drift past and are collected in a nitrogen receiver. Pressure is then released from the vessel, and the oxygen molecules are vented to the atmosphere. At the same time, the cycle is repeated in a second vessel to provide a flow of gas into the nitrogen receiver.

PERFORMANCE DATA