Oxygen produce from 20 to 5,000 cubic feet of oxygen per hour at up to 95.5% oxygen concentration. When electricity and a source of compressed air is supplied, these dependable machines can provide oxygen for any application.

-

oxygen-gas-generator-01

https://intergro.co.th/wp-content/uploads/2018/05/O2-1-350x500.jpg

-

oxygen-gas-generator-02

https://intergro.co.th/wp-content/uploads/2018/05/O2-2-350x500.jpg

-

oxygen-gas-generator-03

https://intergro.co.th/wp-content/uploads/2018/05/O2-3-350x500.jpg

-

oxygen-gas-generator-04

https://intergro.co.th/wp-content/uploads/2018/05/O2-4-350x500.jpg

Oxygen Generator – Advantages

- On Site Oxygen Production : No risk of supply chain failure

- Safety : No more explosion or fire hazards related to filling of cryogenic tanks or with high pressure cylinder storage

- Consistent Purity : Oxygen purity of PSA meets US Pharmacopeia standard (93% +-3%) which can be monitored

- Enormous Saving : 65-70% saving on present oxygen consumption

- Reliability : System designed for 24x7 – 365 days continuous use

- Autonomy : Produce what you use

- Less Operating Cost : Reaches breakeven point within 6 months to 3 years

- Compact System : Less space required. Can be installed on terrace, room or hall

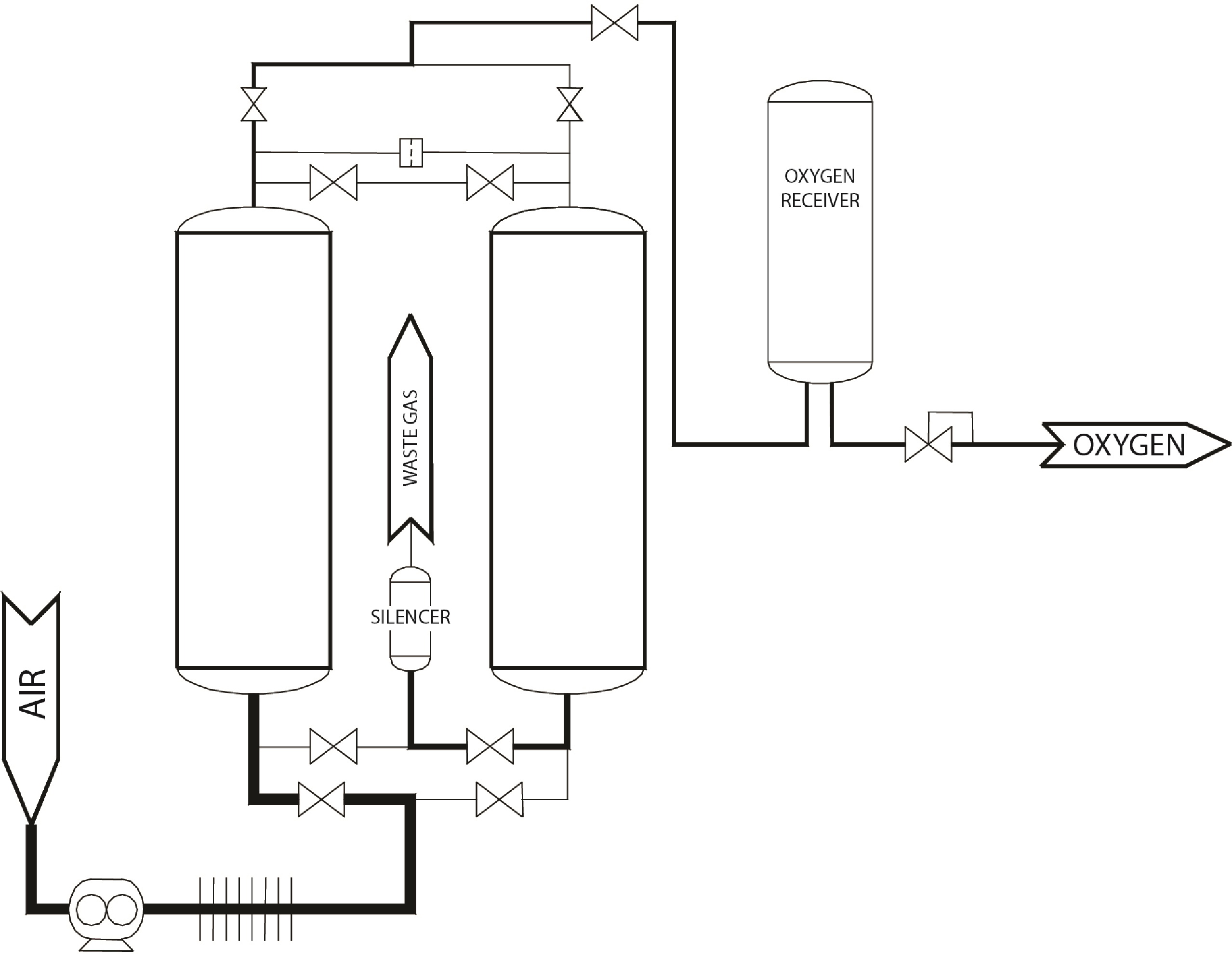

The Pressure Swing Adsorption

(PSA) Oxygen Generating Process

Air contains 21% oxygen, 78% nitrogen, 0.9% argon, and 0.1% other gases. AirSep Oxygen Generating Systems separate oxygen from compressed air through a unique Pressure Swing Adsorption (PSA) process. The PSA process uses molecular sieve (a synthetic zeolite), which attracts (adsorbs) nitrogen from air at high pressure and releases (desorbs) it at low pressure. AirSep Oxygen Generators use two vessels filled with molecular sieve as adsorbers. As compressed feed air flows through one of the vessels, the molecular sieve adsorbs nitrogen. The remaining oxygen passes through the vessel and exits as the product gas. Before the adsorber becomes saturated with nitrogen, the feed air is diverted to the second vessel. At that point, the sieve in the first vessel regenerates by desorbing the nitrogen through depressurization and purging it with oxygen from the second vessel. This process is then repeated in the second vessel to complete a cycle that allows the oxygen generator to deliver a constant flow of product oxygen at 90% minimum purity. Under normal operating conditions, the molecular sieve is completely regenerative and will last indefinitely.