Nitrogen is used as inert or purge gas anywhere, where oxygen reduces the shelf-life of products, impairs their quality or could result in critical or undesirable reactions. Whether your company is specialized in food processing, chemical, electronics manufacturing or laser cutting, a dependable supply of industrial gas is crucial. Compared to the on-demand delivery of gas bottles or tanks, on-site production of gas offers a wealth of advantages ranging from cost savings to continuous availability, this is exactly what we provide.

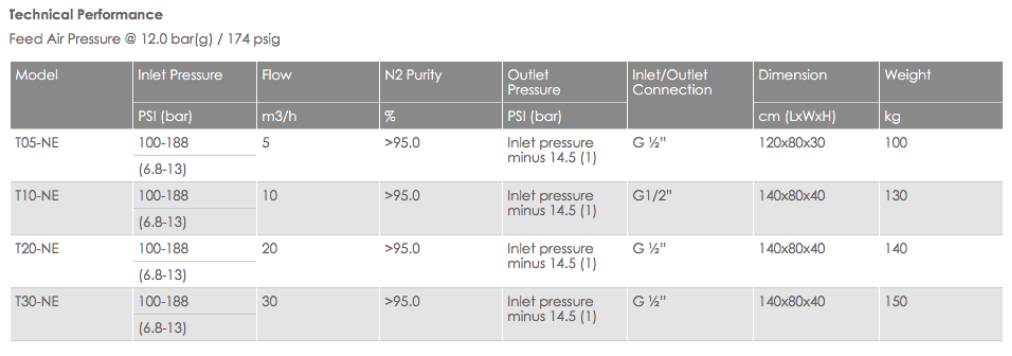

Membrane Nitrogen Generator

With the NGM+ product line, we offers a further option for stationary and mobile nitrogen production. Through the painted memory technology in compact and space-saving construction, small to medium quantities of nitrogen can be produced for the most varied areas of application at low compressed air supply.

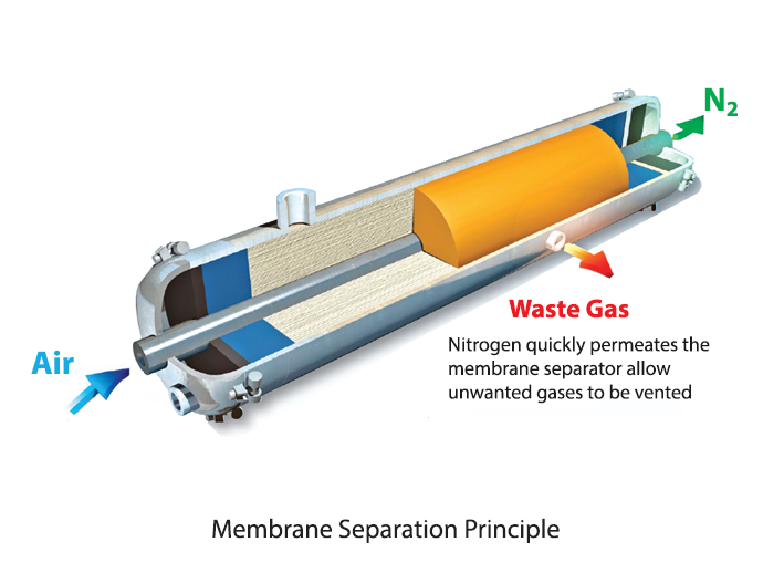

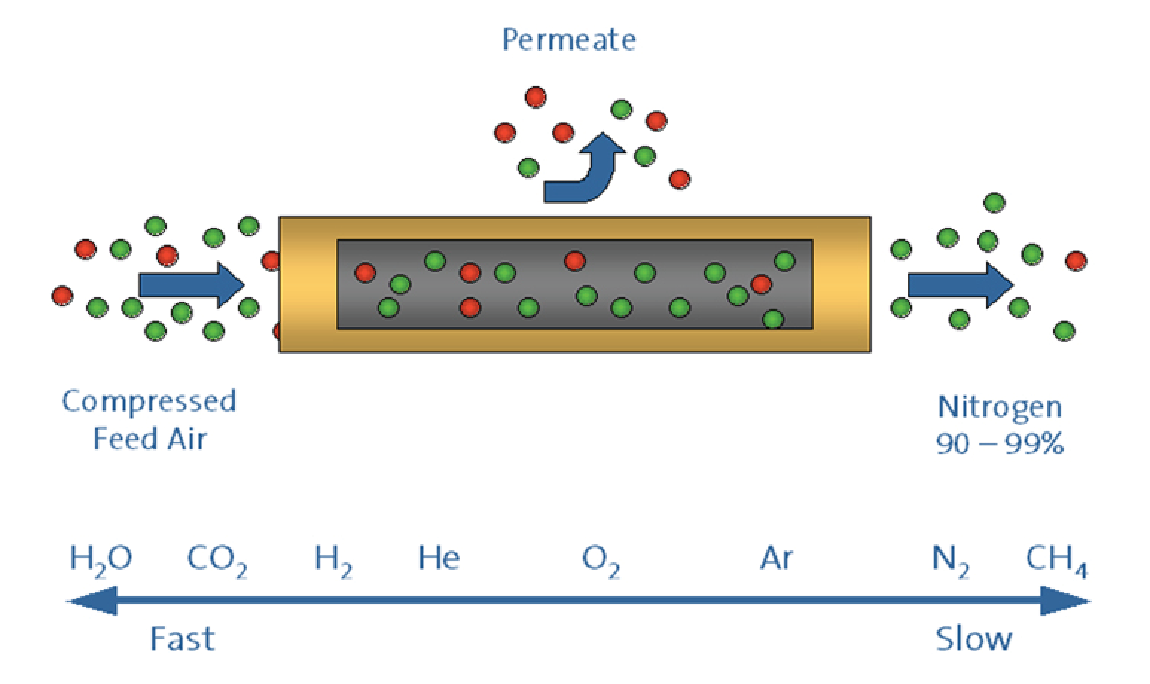

How Nitrogen Membrane works

Membrane nitrogen generators separate nitrogen from the atmosphere by passing compressed air through a permeable membrane. The technology relies on the principle of selective gas permeation. Each gas has a different permeation rate, so as the compressed feed air stream passes across the membrane, the gases with faster permeation rate (such as O2, CO2 & CO) to be separated from “slow gasses” such as nitrogen and the “fast gases” are released back to atmosphere at low pressure as waste gas. While the product nitrogen gas passes through a flow control and a non-return valve into the product receiver, or directly into the customer process line.