Industrial furnaces of various intended uses: for heat treatment, continuous,

low-temperature conveyor, belted. Wide range of foundry products: ladle heaters, bracket drying chamber, tunnel furnaces.

Ovens and dryers

Essiccatoi

FORCED CONVECTION GES OVEN MOD. LM LT3.3G

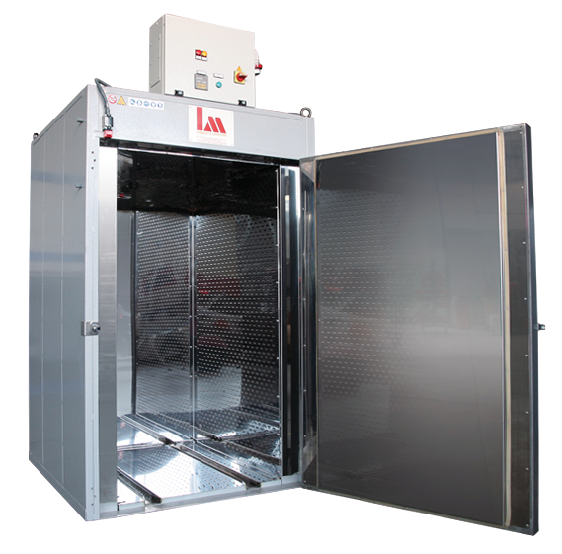

Larger models can be equipped with automatic opening single or double doors, trolley loading manual or motorized, perforated baskets with supports or guides.

BAKING BETWEEN CARBON RIMS OR ALUMINUM WITH SPECIAL CART MOD. LM LT1.4E

Electric fan oven high uniformity in the room +/-1 ° C equipped with a process controller and remote data acquisition module.

STATIC OVEN WITH FORCED CIRCULATION MOD. LM LT11G

In general, we consider low-temperature furnaces ranges between 50 and 450 ° C. They are furnaces with very high internal air circulation to ensure uniformity in all points, equipped with a temperature controller or process controller for cooking step. suitable for treatments of composite materials polymers, light alloys, brake pads, windings of electric motors, provided both electrical and gas with direct or indirect flame.

Forni statici a circolation forzata

OVEN HOT AIR MOD. LMFT-5P/LMFT-12P/LMFTX-10P

The ovens are LMFT dryers forced circulation of air boilers designed to make thermal processes up to 270 ° C, ensure set point accuracy of work and uniformity of temperature within certain tolerances very limited. There are several uses of use: cooking, reticulation, drying, softening, and drying to complete the cycles of attachment to painting.

OVEN TWIN - FLOW CONVECTION

In general, we consider low-temperature furnaces ranges between 500 and 350 ° C. They are furnaces with very high internal air circulation to ensure uniformity in all points, equipped with a temperature controller or process controller for cooking step

Forni a pozzo

OVEN PIT MOD. LM LT0.285TL

Oven entirely made of steel with manual to loading for maximum temperature 180 ํ C. Each product has specific characteristics that are different from other similar but ns. versatility allows us to tailor our models to the most demanding needs