Laser welding machine for welding all type of metal; Gold, Silver, Platinum, steel, Copper, Brass, Aluminium, Titanium. This machine unit particularly suitable for mass production, welding seams, machining times are reduced to minimum. Here the light beam quality makes for an optimum work result. The optional mode aperture enables the beam diameter to be reduced to a mere 0.05 mm. This is of especially great benefit for very delicate workpieces. Performance in repair and production operations.

Laser Welding

SL 20

Developed for small workshops the laser-system SL 20 is characterized by a tremendous compact design.

The device is designed for very small rooms with already pre-assembled furniture. The installation process is easy and quick. With the SL 20 all laser welding tasks of a small workshop can easily be done.

With 5 liters of water cooling the SL 20 is prepared for continuous operation. An efficient welding fumes extraction with fine dust particle filter is integrated as well. The high – quality stereo microscope Leica magnifies 15 times for optimal observation of the welding process.

SL 50

The SL 50 is based on the successful ALS 35 S model.

It is one of the fastest handcraft laser workstations available on the market.

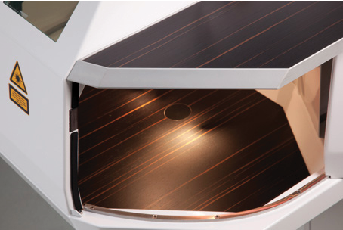

The device is especially suitable for series production due to its max. averaged performance of 120 Watt and a pulse frequency of 25 cycles per second. Processing time is reduced to a minimum, especially when welding seams. The optional mode aperture enables the beam diameter to be reduced to a mere 0.05 mm. This is of especially great benefit for very delicate workpieces. The casing is a welded high-grade steel construction. A working chamber with removable bottom provides additional flexibility in the handling of large workpieces.

SL 75

The SL75 Tornado laser system is designed for multisite operations and mass production applications. Its double flash lamp system offers highest peak pulse power up to 12 KW. The SL75 is perfect to weld materials, which demands a high melting energy like silver, copper and pure gold. The averaged performance of 75 Watt at 15 cycles per second ensures a rapid workflow during production. Two internal heat exchangers provide sufficient cooling for this enormous power. Easy operating by using a shift regulator allows even unexercised users to handle the SL75 in a minimum of practice. The optional mode aperture enables the beam diameter to be reduced to a mere 0.05 mm. This is of especially great benefit for very delicate workpieces. The casing is a welded high-grade steel construction. A working chamber with removable bottom provides additional flexibility in the handling of large work pieces.

SL 100

The new SL 100 in slim design and new housing is one of the fastest laser hand-workplaces on the market.

The maximum averaged power rating of 100 Watt and a pulse repetition frequency of 25 shots per second make this unit particularly suitable for mass production. For welding seams, machining times are reduced to a minimum. Here the high beam quality makes for an optimum work result. The optional mode aperture enables the beam diameter to be reduced to a mere 0.05mm. This is of especially great benefit for very delicate workpieces.

A large dimensioned work chamber decisively simplifies handling larger workpieces. Simple operation with joysticks enables even untrained users to learn dealing with this laser system very quickly. An ergonomic sitting position makes for a relaxed work posture and rounds off the profile.

The new SL 100 is thus an all rounder that proves convincing by its stupendous performance in repair and production operations.

SL 50 – E

The SL 50-E impressively combines topmost efficiency with best workmanship quality made in Germany.

This easy-to-use laser system is therefore cost-effective and practical also for smaller business operations.

Thanks to its maximum average performance of 100 watts and a pulse frequency of 25 cycles per second the SL 50-E handles even challenging tasks and series production reliably and precisely. The optional mode aperture enables the beam diameter to be reduced to a mere 0.05 mm.

A working chamber with removable base provides maximum flexibility for the handling of large workpieces. The high-grade steel casing and the large work surface complete the high-quality image of the SL 50-E.