Industrial centrifuges and machinery for degreasing, drying, and impregnation; automatic systems for superficial treatment; washing and coating systems; and other specific devices for the industry.

DE - Oiling

De - Oiling Centrifuges

MOD. 270

These centrifuges are used for the disoliatura of metal parts. E 'consists of a basket removable stainless steel and self-balancing, for drying and disoliatura of metal parts. It is available on request: Stainless steel frame. Electronic speed variator.

MOD. 360

These centrifuges are used for the disoliatura of metal parts. E 'consists of a basket removable stainless steel and self-balancing, for drying and disoliatura of metal parts. It is available on request: Stainless steel frame. Electronic speed variator.

MOD. 480

These centrifuges are used for the disoliatura of metal parts. E 'consists of a basket removable stainless steel and self-balancing, for drying and disoliatura of metal parts. It is available on request: Stainless steel frame. Electronic speed variator.

Automatic De - Oiling with automatic loading and unloading

MOD. 270

It is used for de-oiling small metal, produced continuously by printing presses. The load is carried on a conveyor belt, the discharge by tipping the basket. automatic loading and unloading.

MOD. 480

It is used for de-oiling small metal, produced continuously by printing presses. The load is carried on a conveyor belt, the discharge by tipping the basket. automatic loading and unloading.

Automatic De – Oiling

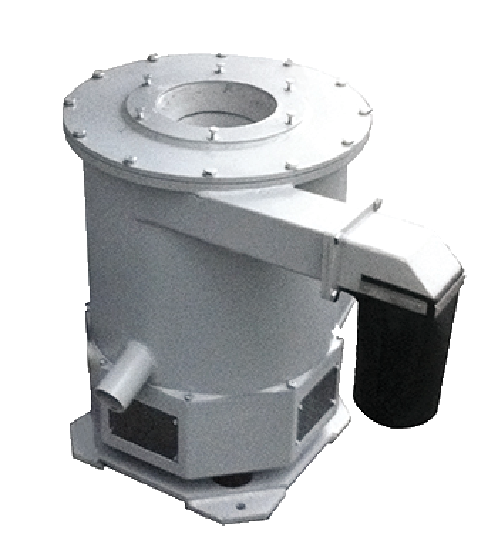

LANDO 1000

The chips, which are introduced through the loading hopper, fall directly on the bottom of the basket and to the centrifugal force effect are pushed upward. Passing in correspondence of the filter sector are freed of the lubricant, then back towards the upper edge of the basket where they are expelled and recovered on the bottom of the centrifuge.

LANDO 2000

The chips, which are introduced through the hopper loading, fall directly on the bottom of the basket and because of the centrifugal force they are pushed up- ward. Passing at the liter sector, they get rid of lubricant, then they go back to the top of the basket where they are expelled and recovered on the bottom of the centrifuge.